LB FEATURES

LBT – Bottom intake, top discharge LBF – Front intake, top discharge Two piece all aluminum, 12 gauge front and back.

- Extended backs and fronts available.

- 4″ junction boxes at each end.

- 3/4″ EMT raceway standard.

- 1/2″ and 3/4″ knockouts.

- Control packages available.

- In house engineering and design assistance.

- Custom selection of convector lengths from 2′ to 12′ length in 1/16″ increments.

- Multiple heater sections on one common back.

- UL and CUL listed.

- Full length thermal limit switch.

- There are 5 anodized finishes available, six durable Decorator painted finishes and grey prime.

- Custom finishes specified by the architect are available.

- Available with optional 2″ pedestals and finished back.

- 1/4″ pencil proof discharge grill.

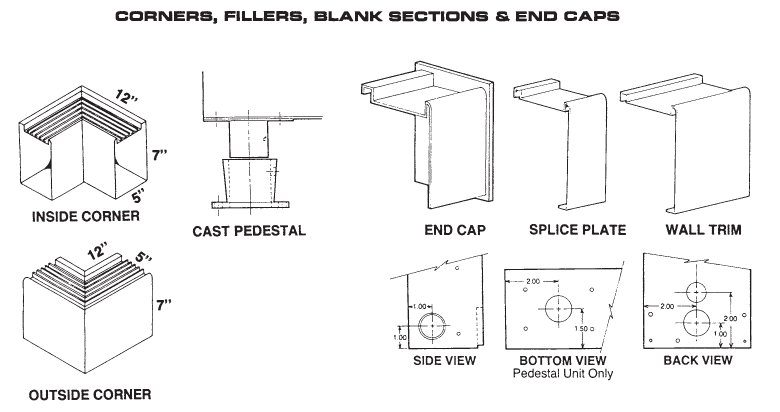

- Accessories include: end caps, wall trims, splice plates, corners and blank sections.

- Cabinet size is 5″W x 7″H.

- Available with built in thermostat or disconnect.

- Wattages from 100 to 500 watts per foot. (Except 120 volt*)

Control sections include 6″ or 12″ with disconnect, thermostat, pneumatic relay, transformer relay, relay, fused disconnect or duplex receptacle Standard built-in controls shall include thermostats (single and double pole) and disconnect switches.

LBT, LBF, LB-PD

Suggested Engineering Specifications:

Model LB Architectural Draft Barriers shall be 7″ high and 5″ wide. The front cover shall be 12 gauge extruded aluminum construction suitable for Architectural, Commercial and Industrial use with 1/4″ pencil proof intake and discharge grills. The one piece cover shall be extruded for maximum strength and shall be available in lengths up to 12′. The cover shall be linear mount to the 12 gauge heater back with no visible fasteners. The 12 gauge heater back shall be suitable for mullion to mullion mounting. Standard painted finishes or optional anodizing (see color chart) shall be provided as specified by the architect. Color matching to architects specifications are available as optional finishes. Heat sections from 2′ to 10′ are available. All heaters shall contain 3/4″ EMT built in raceway with factory wiring to provide field wiring from either end when optional controls are not included. 1/2″ and 3/4″ knockouts shall be provided in the side and rear of the heater junction box to permit end to end wiring. All blank sections shall be fully enclosed to allow branch circuit wiring. All heaters shall contain a full length thermal overheat protector with automatic reset. Wattages shall be available from 100 to 500 watts per foot. Heating elements shall be tubular stainless steel or aluminum tubing with aluminum fins mechanically bonded to ensure efficient heat transfer. Element fin temperature shall not exceed 350 degrees Fahrenheit to ensure long element life. Elements shall be center anchored and free floating in nylon bushings at each end. Control sections include 6″ or 12″ with: disconnect, thermostat, pneumatic relay, transformer relay, relay, fused disconnect or duplex receptacle. Standard built-in controls shall include thermostats (single and double pole) and disconnect switches. Built-in controls shall be tamper proof and shall be adjustable with a blade screwdriver through the discharge louver. All heaters are Underwriters Laboratories listed. LB-PD LB-PD series shall have 2″ adjustable pedestals and the heater back will be painted to match the front cover.

Standard Painted Finishes:

Black, Bronze, Grey, Tan, White, Prime Grey

Available Anodized Finishes:

204, 311, 312, 313 and 315. NOTE: Specify LBT-PD or LBF-PD when ordering.

Furniture, Drapes & Carpeting

Proper operation of heater requires free circulation of room air through the heating element. Keep electrical cords, drapes, rugs and other furnishings away from the heater. Furniture should be placed no closer than 4″ from the heater. Drapes should clear the top of the heater by at least 12″. Or, if you prefer floor length drapes, they should clear the floor by 3″, and the minimum clearance from the back fold to the front cover should be at least 4″. For best results when carpeting is involved in the installation, allow clearance for carpet to be installed under the heaters and corners. Rugs can be placed up to the heater provided that they are not of a thickness that would block the air-intake at the bottom of the heater.

Controls Built-In

LB-ITS (thermostat)

Single pole rated 22 amps, 120 – 227 volt. Adjustable through discharge grill, mounted in right hand junction box.

LB-ITD

Same as Above (double pole.)

LB-IDS (disconnect)

Double pole, rated 20 amps, 120 – 277 volt. Adjustable through discharge grill, mounted in left junction box.

Control Sections LB-CS

6″ Control Section

6″ long and can be added to total enclosure length. Contains 1 or 2 controls. Right or left hand mounting (right hand is standard).

12″ Control Section

12″ long and can be added to total enclosure length. Contains 1, 2 or 3controls. Right or left hand mounting (right hand is standard).

PR (power relay), PE (Pneumatic relay), MDR (mercury relay)

Single or double pole (specify). Rated 25 amps, Low or line volt coils (specify).

TR (transformer relay)

Single pole, rated 19 amps, 120 – 277 volt. Contacts rated up to 277 volt (specify). Coils are 24 or 120 volt (specify).

DR (duplex receptacle)

Mounted on front cover. Rated 15 amps, 120 volt. Snap in type control section mounting.

FDS (fused disconnect)

Fuse block with fuse and 20 amp disconnect switch. Control section mounting.

| *Cat. No. | Description |

|---|---|

| LB-WT | Wall Trim (specify 4″ or 6″) |

| LB-SP | Splice Plate |

| LB-EC | End Cap (specify right or left) |

| LB-IC | Inside Corner (specify miter degree) |

| LB-OC | Outside Corner (specify miter degree) |

| LB-BS | Blank Section (specify length 6″-12′) |

| LBT | Bottom Intake, Top Discharge |

| LBF | Front Intake, Top Discharge |

|

Length

|

Voltage

|

Nominal Watts/Ft. |

Total Heating Watts |

Cat No. |

|

2′

|

150 188 250 375 500 |

300 376 500 750 1000 |

2150 2188 2250 2375 2500 |

|

|

3′

|

100 125 188 250 375 500 |

300 375 564 750 1125 1500 |

3100 3125 3188 3250 3375 3500 |

|

|

4′

|

120*

|

100 125 188 250 375 500 |

400 500 750 1000 1500 2000 |

4100 4125 4188 4250 4375 4500 |

|

5′

|

240

|

100 125 188 250 375 500 |

500 625 940 1250 1875 2500 |

5100 5125 5188 5250 5375 5500 |

|

6′

|

or 277 |

100 125 188 250 375 500 |

600 750 1125 1500 2250 3000 |

6100 6125 6188 6250 6375 6500 |

|

7′

|

100 125 188 250 375 500 |

700 875 1316 1750 2625 3500 |

7100 7125 7188 7250 7375 7500 |

|

|

8′

|

100 125 188 250 375 500 |

800 1000 1504 2000 3000 4000 |

8100 8125 8188 8250 8375 8500 |

|

|

9′

|

100 125 188 250 375 500 |

900 1125 1692 2250 3375 4500 |

9100 9125 9188 9250 9375 9500 |

|

|

10′

|

|

100 125 188 250 375 500 |

1000 1250 1880 2500 3750 5000 |

10100 10125 10188 10250 10375 10500 |